For any surface treatment with dye such as dye painting, stamping, stenciling, any kind of monoprinting, or deconstructed screen printing, I like to pre-treat my cloth in a soak of soda ash, also known as sodium carbonate, also known as fixer or activator in some circles. This prepares the molecules in the fabric with soda ash, so that I don’t have to add any extra liquid to my paint. The fabric is ready and waiting to activate the dye as soon as I apply it. A nice warm day is also good so that you can air dry your cloth outside on the clothesline. You can air dry it inside also; I just happen to like to hang it outside. Just don’t put it in the clothes dryer or iron it in any way, because it will turn brown….something about that high alkalinity…

I buy my soda ash/sodium carbonate at various places, such as pool suppliers, Walmart when they clearance the summer stuff, and Dick Blick. If I am at Festival or Paducah quilt show, I always purchase extra from Pro-Chem’s booth. I never have it shipped to me because of the weight. Of course now, I sell it when I vend at retail shows, so I order it from Jacquard.

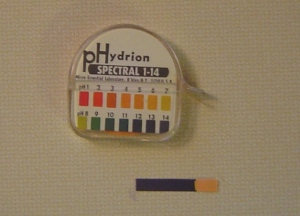

My recipe is to use 1/2 cup of soda ash to every gallon of hot water. Several dyers I know call for 9 tablespoons, but 1/2 cup is 8 tablespoons and gives me a very high alkalinity, as evidenced by the ph tape in the picture below. I learned this from Robbi Eklow. Since I am usually preparing several yards of fabric at a time, I will mix two gallons of hot water with 1 cup of the soda ash in order to have plenty of solution. I use a 5 gallon laundry detergent bucket.

This is one of those cups that comes in every box of granular laundry detergent. I save them for measuring my dyeing supplies. The smaller one is 1/2 cup (I checked), so I quickly measure 1/2 cup of soda ash into my soaking bucket. Then using HOT water (so it dissolves), I stir with a wooden spoon which is reserved just for this task. My ph tape tells me the alkalinity is good, so my pre-soak is ready.

The ph tape is available at both dye houses, Pro-Chemical and Dharma Trading Company.

Now it’s time to soak. Since I purchase PFD (prepared for dyeing) cotton (so I don’t have to pre-wash), I immediately submerge my cloth in the bucket. I know some people go ahead and pre-wash their pfd to remove any oils or dirt. I have never pre-washed mine and have never had a problem with any of it (except there was that one time I got cloth that was marked PFD but it actually had sizing on it…and there was a couple of bolts that even pre-washing didn’t make a difference…that’s a whole horror story all by itself). One little trick I’ve learned since I’ve been doing this for awhile is this: if you find the fabric wants to float in the bucket and not submerge and immediately get wet while you are pushing it down in the water, there IS sizing on it and you should pre-wash it, while hoping it’s not a permanent press finish, because if it is, you won’t get anything other than a pastel color on it. This means it is even resisting the water, which spells trouble.

Soak it 20 minutes or longer, which will not hurt the cloth. Using latex, vinyl or rubber gloves, wring the pieces out and give the cloth a spin in the washer spin cycle. Make sure it doesn’t rinse at all, or you will have to soak again. You don’t want the washer to rinse out your soda ash. Hang on the line to dry, then fold up and keep separate from your other cloth. It may be helpful to mark it in some way. You can keep it this way for a fairly long time before using. Leftover soda ash solution can be saved for a long time and re-used, so don’t throw that away.

I probably should clarify that these are soaking instructions for cotton only! For silk, you can use soda ash or white vinegar for the pre-soak. My experience has been that you will get different colors depending on what the pre-soak is. It’s an interesting side effect. Silk cannot have soda ash on it for very long without affecting it adversely. I do not soak silk in soda ash and leave it. I usually treat silk with white vinegar.

Thanks for sharing your knowledge! When you say the pre-treated fabric can be kept for a fairly long time, do you have an estimate? Also, when you are ready to dye, can you/do you wet the pre-treated fabric before applying the dyes?

Thank you for this information. Knowing I can buy the soda ash/sodium carbonate in local pool supply stores or dept stores is a big help. I didn’t know about the ph tape either. New to dyeing fabric. Thank you, thank you.

You are so welcome Gloria…good luck with your dyeing projects!

Since Arm and Hammer washing soda is sodium carbonate, can you use this instead of purchasing a pool chemical? Also, what do you do with your cotton prints once they are made as a screen print? I’ll be taking a class with Kerr Grabowski but I think she uses a lot of silk.

like lora, i want to know how long i can keep pre-soaked cotton before painting on it. weeks? months? before the ash eats the fiber away.

Sharon, if Arm and Hammer washing soda is strictly sodium carbonate, I see no reason why you can’t use it. I have heard there are other things in it. I use all the cloth I screen print in work for the wall mostly.

Jeanne, I can’t really give you an expiration date on how long to keep your soda soaked cotton. But I do have some left from last summer and it has not been eaten away. I’m not sure you have to worry about that with cotton. Silk is the fabric that you don’t want to leave the soda ash on for very long. But I have never heard of cotton having problems.

hey, thanks for the reply. both silk and wool are allergic to soda ash, so i didn’t worry about it until some t-shirts i made using the soda soak method developed holes in them soon after. this time, i’m making a huge dragon sari, and am hoping for the best.

a huge secret revealed…soda ash is sodium bicorbonate,

it can be expensive when bought in bulk,

I have found that arm n hammer washing soda is exactly the same and is inexpensive and found at most grocery stores

thank you, sonia for the soda ash/sodium bicorbonate clue. I am rust dyeing in Nairobi, Kenya and materials are not always available.

Julie, let us know how your dyeing goes. My understanding is that soda ash is sodium carbonate…baking soda is sodium bicarbonate. I don’t believe that they will do the same thing. I once accidentally bought the bi-carbonate in the swimming pool section, but when I discovered it I was too scared to use it. Check online about the differences.

I’m going to be preparing first piece of cotton for painting and wondering how many yards of fabric can be safely soaked in your half cup soda in 1 gal. hot water,

thanks

ct

Thanks so much for the info i’m dyeing fabric with ice and dye and let me tell you WOW i love color i fill like it gives me energy lol .

I know EXACTLY what you mean! I’m a color freak too! All my dyeing life I’ve been taught that one must have 70 degrees or higher to get good colors with procion mx dyes. When people started doing ice dyeing, I scratched my head! Anyway, I haven’t given it a go yet, but it’s on my list of things to play with and soon! Thanks for commenting.

Katherine Sands creator of wild hand dyed fabrics kathy@katherinesands.com http://www.katherinesands.com blog at http://www.katherinesands.wordpress.com In God I Trust

CT, I am just now seeing your post…so sorry. You can probably soak about 6 yards of fabric in that gallon of water, say three at a time, take them out and add the next three. I loosely wring them out as I take them out…keeps the water level up.

For rust dyeing, I don’t use soda ash and I’m not sure you need to. I use a white vinegar soak and wrap the rusting items in the cloth…let sit for a day or two depending on how much rust I want on it. Some people use a vinegar/water mixture.

Kathy, I just looked at my Arm and Hammer Washing Soda and it says “contains sodium carbonate.” It does not say that sodium carbonate is the only ingredient. I don’t trust it. Getting ready for Tuesday and looking at your formula.

Hi Kathy,

I have some left over soda ash fixer powder from 2 summers ago that I would like to use for another tie-dye project this year. Do you know if the unmixed powder has a shelf life? It has been stored in an airtight ziploc bag.

Thanks!

Hi Anna, Thanks for writing. I’m sure the soda ash will be just fine. As far as I know there is no shelf life on it. It is the stuff they put in swimming pools, so I don’t think time affects it…perhaps 20 years or so…but not sure about that either!

Katherine Sands creator of wild hand dyed fabrics kathy@katherinesands.com http://www.katherinesands.com blog at http://www.katherinesands.wordpress.com Author of “A Tale of Two Lambs”, published spring 2013 In God I Trust

Thank you!

Hi Kathy,

I am hosting a tie-dye party next weekend! Up to how many t-shirts should I soak in soda ash solution at once? Is it possible to soak the shirts in the soda ash, wring them of excess liquid, and then go straight to dyeing? And from what I read in your post, it would be best to have guests pre-wash their shirts before coming to the party, right? Sorry for the excessive questions. This is my first time tie-dyeing!

Hi Christine, I hope you got my reply a few days ago to your question. I sent it from my email account which usually posts here, but didn’t this time, for some reason.

Kathy

i have a kit from michaels (beginner i am) it says it has soda ash in the kit already and to just wash the shirts first. should i still soak the shirts in soda ash (also can i use white vinegar and water) ?? My goal is to have brighter colors than i did the last time i tried at a church on cape cod last summer. Is there anything to soak it in after? thanks Christine

PS Like Your site!!

Hi Christine, and thanks….so glad you like my blog.

If you are looking for better colors on your shirts, may I suggest leaving them to sit overnight (if you didn’t the first time) as the way to enhance the colors. My experience with the kits is that there is enough soda ash in them and the shirts I did with them were very colorful. I don’t believe a pre-soak is needed in extra soda ash, but it won’t hurt to do it. My understanding about pre-soaking is this: the dye immediately begins to “strike” when hitting pre-soaked fabric (or shirts). With the kits, you are mixing the dye and soda ash with water (at least the ones I used did), which starts the chemical reaction immediately before you get it on the shirts or fabrics. If some time elapses before you get this mix on the cloth, you are indeed losing some strength in the dyes.

I hope this helps. Thanks for commenting.

Kathy

In answer to your other question…vinegar is NOT the pre-soak for cotton (fabrics or shirts). It is used for silks.

There is nothing you need to soak it in afterwards. Let the dyes sit on the shirts for 4 hours at a minimum and 24 if you like. Rinse in COLD water several times before washing in hot water to remove the excess dyes.

Soda ash is NOT sodium bicarbonate, it is sodium carbonate. It is molecularly different. Soda ash is more reactive and less stable. It is a lot cheaper the bi carb.

Thanks for clarifying that, Teleskier….you made me think I had said it was Bi carbonate…and I didn’t think that I had..

Great tutorial! Thanks so much. I typically create batik as fine art and therefore have not needed to use a soda ash presoak as my batiks are ironed and framed and never washed. I am wanting to batik for craft purposes and this tutorial is really helpful. I did have one question though. You stated to not iron the pretreated fabric due to browning. Does this also include not ironing after dyeing and waxing as a wax removal technique? Thanks!

Thanks for reading, Jane. No, after waxing and dyeing, that is not a problem. I have a friend who made some really large dyed panels and she did not rinse the excess dye out. After a while, the excess dye turned into a powder and and flaked off the artwork. I am not sure it is good to breathe it.

Thanks Kathy!

Kathy…what an awesome blog! I read through all the advice and I have a question. I am an art teacher that is putting together a fine arts festival with 8 schools. There will be 42 people(adults and high school age) that I would love to have do a tie die on shirts. From reading your blog, I am thinking that I will need to pre-treat all the shirts with soda ash, then dry for them.

What would you recommend to be the best dying for large groups? I was thinking squirting the die on the crumpled/band tied shirt? We are also in an area that we have to be as clean as possible 😦 (not my choice) We are going to do a lino cut on top of the dye within hours. Do you think that would cause any problems with the lino print bleeding out on the wet dye background? I want to make sure the kids get a nice, clean lines print. I believe the fabric printing ink has to stay on fabric 4 days before washing…is it alright to wait that long with the dye?

I will do experimenting as well, but I was hoping you might be able to help with a couple of the questions 🙂 Thank you so much!!!

Baking soda WILL work, but first add it to water, heat until it incorporates, sodium bicarbonate becomes Soda Ash at 122 degrees Fahrenheit. Once your there, it’s usable. C-;

Hi Paula, and thanks for your questions. The problem I see with what you are asking is that it is two different processes that each need a different environment, which may be difficult to accomplish in the same day. Here’s the deal….Your shirts need to be plenty wet so that the liquid dyes will spread and do a decent job of depositing color. Then it needs to sit wet in a plastic bag or covered tub for 2-4 hours for good color. After that, if you want to print without the image running, it needs to be dry. You would need to rinse them a couple of times, then wash and dry them. Since you mentioned using fabric printing ink, you don’t need a fixer (like the dyes need) for that. My experience with the printing ink was that it washed out too easily without an extremely GOOD heat set OR there is a product that can be mixed with the ink which does not need the heat set and makes the ink permanent. You may have some different inks with different requirements for permanency.

Walmart (and other places) sell tie dye kits which have the soda ash already in the bottles with the dye powder. This makes it very easy to dye shirts with. I did a kids’ class with these kits…it made the whole process very easy. We got their shirts wet (did not need extra soda ash, I just used water), tied them, and squirted the dye on, then the shirts went in bags to do the wait time. They were washed later that day, but we didn’t do any extra printing on them.

Hope this helps…you have your work cut out for you!

I would plan for an evening printing session if you want to do it all in one day, or at least late afternoon.

Hi Mandi, I have never heard anyone share this before about baking soda. You may be right, but I’ll probably just stick with purchasing soda ash and avoid an extra step that takes time. What I do already takes plenty of time! The only thing I don’t do is weave the cloth…and I’m not even going to go there.

Paula, one more thing about keeping the area clean…make sure all the kids work inside a dish tub or some sort of container that is big enough. I use plastic shoeboxes for the bottles and cups of dye when I teach…too many accidents. Everything sits in the shoe boxes after mixing. The shoeboxes confine the dyes if someone knocks something over. I make sure to cover the tables with a light plastic drop cloth and the floors too. You’d be surprised who gets it on their shoes and walks around leaving dye footprints. Everyone needs to wear gloves while handling the dyes. Make sure there is rinse water in a tub or shoebox for everyone to get to. Just some tips to help minimize mess. When I teach a basic fabric dyeing class, we do it in plastic bags; it’s the cleanest method out there.

Kathy~Great ideas! We will be there all day, from 8am till 6pm. I am thinking that I can do the bottle mixing dye, placed in the bag you mentioned. Maybe they can keep it in the same bag to set up for 2-4 hours. Then we can go to a lino lesson while it is setting. Go to lunch, come back and wash out. Then possibly use a heat gun to dry the section of the shirt that the printing is going to adhere to? Kathy, I really appreciate your opinion, thank you so very much for your time on this. ~Paula

oh yes, the bag is to leave it there for “batching” (which is the term used in the dyeing world for letting it sit in the dyes) Yes, a heat gun would work to get the section dry enough. Dry would be good, but even a bit damp probably wouldn’t hurt. Those inks are thick. Good luck!

Thanks for your advice and tricks of the trade! I’m out of my area of expertise on this one-lol Your wonderful.

Your plan sounds good…I would definitely go for the 4 hour batch if you want brilliant colors.

one more thought…use gallon freezer bags, slide lock…. reason? regular bags are too thin and can bust (they can squish the dye into the shirt from the outside of the bag) and the slide lock bags can be handled with gloves. I always use freezer slide lock bags.

You are most welcome…I have been teaching dyeing for a number of years. I have learned along the way what works the best and have taught it in carpeted areas and nice gymnasium floors. I think I have seen it all. lol! The shoebox idea came after a lady knocked over a whole cup of liquid dye in the gymnasium, then got it on her shoes. After that I said they are going to mix inside another container!

Super idea. I love the small hints that make things easier! I will definitely go that way. 🙂 I will be experimenting this weekend. 🙂

Kathy,

I am sorry to ask but…But with your vast knowledge in teaching this…Do you buy specific colors of dye when your teaching? Or do you go with the standard primary colors that everyone can mix?

I am trying to figure out if I should get specific colors with 42 people (like a set of cool colors~blue and purple and a set of warm colors~red and yellow) for all to choose their cool or warm color scheme from, in a station format… Or go with a already assorted color scheme right from Jacquard that I can put on their table-like the primary scheme that they themselves can mix on the shirts (the schools will have their own table of 6 people to share).

Last question…I swear! LOL

Thanks,

Paula

Hi Paula 42 people is a lot of people. I would probably simplify this as much as possible. When I did the large class, I think I bought two different types of kits so there was a bit of choice, but the kids didn’t really care, they just went for it. You could have a variety of colors and let them make choices…you would just need to have plenty of dye for that many people. I might choose 10 colors or less (not sure how much variety you want) and have plenty on hand. Just let them choose which colors they want to use. The printers primaries are lemon yellow, fuchsia, and turquoise. Other variations that I have used before would be indigo, red and golden yellow. Good luck! That is a lot of people!

I am interested in dying silk. Can you give me more details about how much white vinegar is needed per gal of water?

Joni, I generally use the vinegar full force, but I have read where others dilute it by half. Hope that helps.

Hi my name is Angela. I am happy to have read your comments on how to use the soda ash and saving it as well. Good information. I am preparing a wedding gift for a friend, tie dye bed sheet and pillow cases. Excited about the results. Thanks for your help

You are so welcome, Angela. I hope everything comes out beautiful!

How can i send you a picture of my final product? Smile

Angela, you can send it to kathy@katherinesands.com. Thanks!

HI, I am planning on putting a design on my tie dyed shirts and am planning to draw it on with dye resist (Tulip brand) after pretreating with soda ash and before dying. Have you ever used this? If so, how does it work and do you have any recommendations? Thanks!

Also, does it matter how long you leave the shirts in soda ash? I left one batch in over night (about 10 hours). SHould I leave the second batch in for about the same amount of time in order to get as much of the same result as possible? Again, thanks!

Hi Lori, I have not used Tulip resist. My guess is that it will be acrylic and will stay permanently on your shirt. The dyes won’t affect it as the acrylic “seals” your design in the shirt. I have used other acrylic products to create a resist on fabric and then dyed over it. The dyes don’t bother it at all.

The soda soak really only needs 15 to 20 minutes. Extra time in that doesn’t guarantee extra color. That is determined by how much time cloth is left in the dyes.

What an interesting site. I am taking a 3 day workshop dying fabric and surface design. It was suggested that we do a soda wash to get the fabric ready for use. This answered all my questions. I have Arm and Hammer Washing Soda on hand to use. I am happy to have found this information. Thanks.

Hi Pat , Thanks for writing.

Regarding soda wash to prep fabric: I don’t merely suggest it! I MANDATE it!!! For printing the fabric simply must be ready to receive the dyes IF you want crisp images. If you want a softer look, the soda ash could be applied as you print. A squirt bottle is one way, or mix it with the dyes or dye paint, in which case, you have to work fast because the chemical reaction starts when you mix the dyes and soda ash together.

I hope the washing soda works for you….a previous commenter said the box says it “contains” sodium carbonate. I have not used it so I cannot weigh in on its effectiveness. Perhaps someone else can tell us if they have used it and had the same results as using straight sodium carbonate?

Great info! Thanks so much for sharing your craft. For an easy and inexpensive resist, I’ve been using Elmer’s gel glue. It’s easy to draw with and doesn’t drip. I let it dry on the fabric over night, then scrunch and spray my dyes. So far, so good. You can see a shirt I finished here: https://www.facebook.com/photo.php?fbid=883313145017077&set=pcb.883314401683618&type=1&theater

Again, thank you for sharing your expertise. I am a novice and eager to learn as much as I can. I’m still trying to figure out the dyes. I haven’t used soda ash, yet. Next on my list. Thanks!

Hi Kathy. I previously tie dyed a t-shirt in a horizontal stripe pattern. Now I want to add a heart design on top of the previously dyed shirt. Should I soak the shirt in soda ash? Will it affect my previous design on the shirt?

Are you going to paint the heart on with paint or dye? That will decide. If you are going to use acrylic fabric paint, you don’t need to soak the shirt at all; you should paint it on a dry shirt. If you are going to use thickened dyes, you will need the soda ash. Let the shirt dry after the soak, then paint your heart on and let it batch or sit for 24 hours covered in plastic, then wash. It will not affect the previous design, EXCEPT where the heart hits the stripes, the colors will change. Hope this helps and is clear as mud!

Using the above method can you tell me can I print on my fabric with my inkjet and will it make it colour fast

Hi Lizzie, I have never heard anyone teach that. A product called Bubble Jet Set is the product to use with your fabric and inkjet inks. I have never messed with it. I purchase prepared cotton sheets. Sorry I can’t be any more help than that.

Thank you, I’m going to give it a try!

What good information. Noticed above a comment that “wool and silk are allergic to washing soda”, but didn’t see a response. My experience has been different, at least in terms of silk, as washing soda has been my only setting agent, whether for cotton or silk. Recently, as a result of basic instructions from Dharma, have been limiting the soak time to just a few minutes, as well as the amount of soda to 1/4 c/gallon water. Over the years I’ve seen no damage to the cloth, nor trouble with colors. What am I missing other than the simplicity of using white vinegar?

Actually, Kathryn, I too have used soda ash on silk with no repercussions. The colors are different using soda ash than when using vinegar, which was a huge surprise! I don’t think you are missing anything! There is blog post on here somewhere showing the differences between using soda ash and vinegar on silk.

I am a little confused about the soda ash prep. I only tie dyed in the 60’s as a child using ritz dye. I would like to purchase a 100% cotton shirt I would then… submerged in the soda ash and water solution for about 20 minutes. Wring out by hand and air dry.? When ready to apply dye I must re-wet the soda ash prepared cotton shirt, wring water out completely, form and wrap etc…the shirt the way I want design pattern, rubber band the formed shirt, apply the dye colors of choice, saturating pretty well, flip over and repeat the other side. Place in a zip lock baggie and let it sit undisturbed for 24 hours. Take to a sink or tub and rinse with running water excess dye until clear, then put into washer, using hot water and laundry soap,wash, repeat several washes using cooler water temps until rinse water is clear. Is soda wash toxic? I would definitely wear a mask, goggles and rubber gloves but it concerns me that this product comes from pool supply store. Can I wash the dyed shirt in a 5 gallon bucket rather then using my washing machine? I would not want dye staining the washer rim and drum. Thank you for your help. This is just something I wanted to try out as a small DYI project. But I am wanting to do this right or not at all. That is the way it is for me!

You don’t have to do all that. The pre soaking and drying I only do when I am going to paint on things with thickened dye. For what you are doing, simply get the tshirt totally wet all the way through. Hand wring. Tie it, clamp it, wrap it, whatever design you want to make. Pour the dye on it, wait a few minutes, then pour the soda ash all over it. That makes the dye activate and become permanent. You want the shirt wet because the dye will move through it. It won’t if the shirt is dry. You can put the shirt in a plastic bag before you put anything else on it. This will keep it contained, clean, you can squish the dye around in the shirt from the outside of the bag. Using plastic bags is a clean way to dye. I teach it that way in my classes so the area stays clean. But if you are doing yardage, like I do, I don’t use bags. I can get 4 yards comfortably in a sink size plastic tub, which is what I use when I dye a lot of yardage. Good Luck. Try clamps on your shirt. They make very fun designs.

When you say” pour the soda ash all over it” that would be after mixing 1/2 cup per gallon of warm water? Won’t that flush the dye out of the fabric? Do I also put in a squirt bottle to apply soda ash liquid? That way I can control the amount of liquid being released? Do you wear a mask? Also what size clamps and where do you apply them. Thank you so much for your time and expertise. When I get time in the early evenings I will be checking out your website😉Kathleen

I forgot to ask, “where can I buy the fabric dye?” Joann fabrics, Michael’s or Internet ? Thanks again!

Great site. Thank you for doing this. Will soda ash hurt screen printed fabrics? I’m having drawstring bags printed with a slogan and then want to tye die them. I usually pre-soak in soda ash but have never done anything with something printed on it. Thanks

Screen printed as in a professional manner? Or are you talking about vinyl, the way most t shirts are done these days?

I have no experience with soda ash on t-shirts with vinyl, so I can’t really address that. But what about doing the dyeing before the bags are printed? Is that possible?

i have just completed my first tie dye project. i tie dye a king size cotton sheet to use as a backing for a quilt i am making for a wedding gift. also there was the fitted sheet, pillow cases, and my daughter did some t-shirts. i pre-soaked in soda ash, line dried them, dyed them let sit about 40 hours, rinsed, hand washed all separately, rinsed, and lined dried. the sheets i did put in the washer after hand washing to rise and spin before line drying. my question is can i now wash them all together in my machine and dry in the dryer? or do they need to be individually washed. and line dried again. we are having unseasonable warm weather here in Massachusetts, and i could dry them outside today. thank you

Yes you can wash them all together! The water may still show some dye coming off the sheets but don’t worry it won’t harm anything. The dye is now done reacting and won’t “stick” to anything. A big project doing sheets!

thank you for the information. i was hoping i could wash them together. 2 king sheets, 2 pillowcases, and 3 t-shirts.

it was a big project especially for my first time., but my nephew and his bride to be are into tie dye big time. he proposed at a tie dye shop. if i remember i will send you a finished picture. thanks again. i’m glad i found this tutorial .

Hi. My question is does the amount of soda ash in the solution dilute as it is absorbed by the cotton fabric? Do you have to add more soda ash to the remaining liquid for new fabric?

No you do not.

Thank you. Am exploring ice dying and new color combinations. Breaking out of old habits while learning a new craft.

Hi. My name is Emmanuel. What is the function of urea when tie and dyeing and does salt improve the brightness of colours.

Thank you so much for this! I keep reading instructions with very vague instructions where the ratio of soda ash to water vary great or are not stated at all. I’m a very science-based maker so I was having to do a lot of mental gymnastics to try to guess the proper concentration level. You solved my problem with the pH test strips! As long as my pH is good, then it should work.